Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Microcontroller Based System for Detection of Harmful Chemicals on Fruits and Vegetables

Authors: Sunku Uma Maheswari, Shaik Mohammad Adil, Thummala Vamsi, Geetha Charan, Segiji Sravan Muni Kumar, A Krishna Mohan

DOI Link: https://doi.org/10.22214/ijraset.2024.60541

Certificate: View Certificate

Abstract

Resources are getting limited with the increasing population. The incessant drive to meet food demands compels farmers to augment crop production using both natural and artificial means, including chemical fertilizers and pesticides. While these substances safeguard crops against pests and fungi, their excessive use compromises food quality and poses health risks due to their infiltration into the food chain. Recognizing this issue, there is a pressing need for a portable device capable of analyzing the organic composition of edibles. This study endeavors to ascertain both organic and inorganic elements present in food items, empowering consumers to make informed choices about their consumption. Central to this research is the development of an electronic device utilizing infrared technology to detect chemical residues. By displaying the ratio of organic to inorganic components, consumers can utilize this data as a guideline for selecting safe-to-consume food products,here we are proposed a portable device which makes it easy to identify whether the fruit is organic or inorganic based on this consumer can conclude what to eat and what should not eat.

Introduction

I. INTRODUCTION

India ranks second globally in vegetable and fruit production, trailing only China, accounting for 13.4% of the world's total output. With a population of 1.25 billion, approximately 110.7 million Indians are engaged in farming. Furthermore, India holds the fourth position worldwide in agrochemical and fertilizer production. Surveys conducted by various institutions reveal that between 50-70% of vegetables and fruits harbor pesticide residues. The escalating population places immense pressure on food resources, leading to the adulteration of food to meet demands swiftly, amid diminishing farmland. Moreover, farmers often exceed the WHO-defined legal residue limits for pesticide use on crops. Despite being vital for human nutrition, fruits and vegetables are tainted with chemicals utilized to combat pests, presenting health hazards. Many market-available produce items are either artificially grown or contaminated with pesticides. Common additives like calcium carbide/ethephon and oxytocin exacerbate the issue. The assessment and detection of adulterants in fruit juices emerge as significant research endeavors. Over time, industries have benefited from the widespread use of inexpensive chemicals, compromising the integrity of food. While pesticides effectively combat pests, their residues pose significant health risks. Without proper intervention, pesticide usage is poised to escalate in the future. The Normalized Difference Vegetation Index (NDVI) serves as a tool to quantify vegetation health through remote sensing. NDVI calculates the difference between near-infrared (NIR) and red light reflectance, with values ranging from -1 to +1. Negative values typically denote water bodies, while high positive values indicate dense vegetation. Conversely, values close to zero suggest non-vegetated or urbanized areas. NDVI remains a prevalent index in remote sensing analysis, aiding in land cover classification.

II. EXISTING SYSTEM

High-performance liquid chromatography (HPLC) is a powerful analytical technique used to separate, identify, and quantify components in a mixture. It's widely employed in various fields like pharmaceuticals, chemistry, biochemistry, and environmental science. Here's a brief overview of how it works:

A. Principle

HPLC relies on the interaction between sample components and a stationary phase within a column, as well as the mobile phase (solvent) flowing through the column. Components with different affinities for the stationary phase will travel through the column at different rates, leading to separation.

B. Components

- Column: The heart of an HPLC system, where separation occurs. It's packed with a stationary phase material.

- Pump: Provides the necessary pressure to push the mobile phase through the column at a constant flow rate.

- Injector: Introduces the sample into the mobile phase stream. Detector: Monitors the eluent leaving the column, often using UV-visible spectroscopy, fluorescence, or mass spectrometry.

- Data System: Collects and analyzes detector output. Process: The sample is injected into the mobile phase stream, typically through an injector valve. The mobile phase carries the sample through the column packed with the stationary phase. Components of the sample interact differently with the stationary phase, causing separation. As components elute from the column, they're detected and recorded by the detector. Based on the retention times and peak areas, the components are identified and quantified.

C. Types of HPLC

Normal Phase HPLC: Stationary phase is polar, and the mobile phase is non-polar. Reverse Phase HPLC: Stationary phase is non-polar, and the mobile phase is polar. Size Exclusion Chromatography (SEC): Separates molecules based on their size. Ion Exchange Chromatography (IEC): Separates molecules based on their charge.

D. Drawbacks of Existing System

While HPLC is a powerful analytical technique, it does have some drawbacks: Cost: HPLC systems can be expensive to purchase, operate, and maintain.

The initial investment in equipment, columns, solvents, and other consumables can be significant. Complexity: Setting up and operating an HPLC system requires specialized knowledge and training. Analyzing results and troubleshooting issues can also be complex, especially for inexperienced users.

Sample Preparation: Sample preparation is often required before analysis, which can be time-consuming and may introduce errors or variability.

Solvent Usage: HPLC typically requires the use of organic solvents, which can be expensive and may pose safety and environmental concerns. Additionally, the disposal of used solvents can be a challenge. Column Lifetime and Stability: HPLC columns have a limited lifetime and may degrade over time, leading to decreased separation efficiency and reproducibility. Column stability and reproducibility can be affected by factors such as temperature, pH, and sample matrix.

III. PROPOSED SYSTEM

A proposed sensor system comprises a self-contained device containing a sensing element (e.g., IR sensor) to identify the analyte and a transduction element (ADC) to convert the analog signal into the required digital format. Moreover, their lower cost, ease of design, and compact size position them as excellent candidates for portable device development.

The primary aim of this proposed research is to design and develop a sensor-based system for pesticide residue detection in food. The research involves designing a circuit to interface multiple sensors with the circuit to obtain average values for the subject. Initially, a power circuit is designed to provide a 5V output to microcontrollers, sensors, and LCD.

Two IR sensors and photodiodes are interfaced with the microcontroller, serving as transmitter and receiver, respectively. Subsequently, a filter circuit is designed to amplify the input received from the IR circuit, providing distortion-free amplified output to the microcontroller.

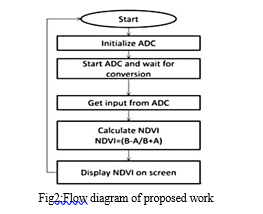

The microcontroller's ADC converts analog input into digital signals, and the Normalized Difference Vegetation Index (NDVI) is calculated using the formula:

NDVI=B-A/A+B,where

A represents the Red light band

B represents the Infrared Band.

The values for different subjects are calculated, matched with their true values, and the error is determined

IV. HARDWARE DESCRIPTION

The hardware setup comprises various modules, including the Microcontroller, LCD display, Photodiode, IR sensors, and a battery source. Infrared (IR) communication stands as a widely utilized technology, exemplified by the commonplace TV remote control, which transmits IR signals to a TV. In this scenario, the remote's IR light toggles on and off repeatedly, typically at 38kHz or 38,000 times per second. IR technology offers affordability and invisibility to the human eye as its advantages. However, its drawback lies in the necessity for direct alignment between the IR light source and the receiver. Hence, IR communication is unsuitable when sender and receiver are situated in different rooms, where Bluetooth or WiFi may present superior alternatives. IR LEDs emit light in the infrared frequency range, which is invisible to the human eye. This wavelength, ranging from 700 nanometers to 1 millimeter, extends beyond the visible light spectrum. Objects that generate heat, such as the human body, emit infrared radiation. Similar to visible light, infrared light can be focused, reflected, and polarized. Thus, IR communication occurs within this wavelength spectrum.

V. SOFTWARE DESCRIPTION

Arduino Uno is a versatile microcontroller board widely used in electronics projects. It features an ATmega328P microcontroller, offering 14 digital input/output pins (of which 6 can be used as PWM outputs), 6 analog inputs, a USB connection for programming, and power, a 16 MHz crystal oscillator, a power jack, an ICSP header, and a reset button. With Arduino Uno, you can create a wide range of projects, from simple blinking LED lights to more complex robotic systems. Using the Arduino IDE and programming language based on C++, you can easily write code to control sensors, actuators, displays, and other electronic components. Arduino Uno's simplicity, affordability, and extensive community support make it an ideal choice for beginners and experienced makers alike. Whether you're learning about electronics, prototyping a new product, or experimenting with creative ideas, Arduino Uno offers a user-friendly platform for bringing your projects to life.

A. Arduino Integrated Development Environment (IDE)

The Arduino Integrated Development Environment (IDE) primarily utilizes a simplified version of the C and C++ programming languages. These languages are used for writing code to control Arduino microcontroller boards and interact with various electronic components such as sensors, actuators, displays, and more. Arduino's variant of C/C++ includes additional libraries and functions specifically designed to simplify hardware interaction, making it easier for beginners to get started with electronics and programming. The IDE provides a user-friendly interface for writing, compiling, and uploading code to Arduino boards, making it accessible to a wide range of users, from hobbyists to professionals. Overall, the Arduino IDE, with its support for C/C++, is a powerful tool for prototyping, developing, and experimenting with electronic projects and embedded systems.

VI. RESULTS

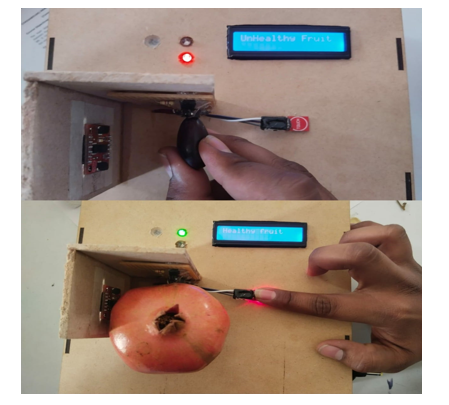

This section elaborates on the design and implementation of a device aimed at detecting Organic and Inorganic Components using the Normalized Difference Vegetation Index (NDVI). Initially, a sample is positioned infront of an IR emitter, exposing it to infrared rays, as depicted in Figure . Subsequently, photodiodes capture the reflected rays and transmit the values to a microcontroller. The input signal undergoes conversion into corresponding voltage values via the Analog-to-Digital Converter (ADC) within the microcontroller. By assessing the disparity between transmitted IR light from the IR sensor and received light by the photodiode, the ratio of organic to inorganic content is determined. This value is then transformed into NDVI utilizing the provided formula and subsequently displayed and illustrated for healthy and unhealthy fruit . NDVI computation is achieved via the equation: NVDI = (NIR - RED) / (NIR + RED). The graph in figure illustrates NDVI values computed by the device for both organic and inorganic subjects, with the red line indicating NDVI for inorganic subjects and the blue line representing organic subjects. In figure , a graph depicting homegrown organic oranges and infected oranges is presented. Noticeable deviations from the true organic content value are observed in infected oranges, with the blue line illustrating homegrown oranges and the red line representing oranges infected with pesticides._

Conclusion

The developed device utilizes Near Infrared (NIR) rays to assess the organic content of food items, offering a cost-effective and dependable method for determining their suitability for human consumption. This innovation serves to raise awareness among consumers and aids them in evaluating the safety of their daily food choices. By obtaining the Normalized Difference Vegetation Index (NDVI) without the need for sample collection or food item damage, the device enables hassle-free analysis of various food items in households, ports, shops, and beyond. With instantaneous organic content values provided, there\'s no longer a need to wait for lab results, surpassing the efficiency of previous detection devices, particularly for pesticide detection. Thorough error coefficient verification against original values ensures high accuracy, especially for routine use. Unlike conventional methods that demand time and sophisticated lab equipment, this device offers a user-friendly alternative accessible to the masses, with each unit affordably priced under Rs 4000/- and powered by AA batteries at 5V. Its portability and ease of use empower individuals to safeguard their food safety. Future enhancements may involve increasing the number of IR sensors for more reliable NDVI calculations, integrating advanced sensors to detect additional contaminants such as weedicides and fungicides, and incorporating additional parameters for enhanced pesticide detection.

References

[1] Development of an Embedded System for Pesticide Residue Detection of Fruits and Vegetables [2] Quality and Pesticides Detection in Fruits and Vegetables [3] Hand Device For Pesticide Detection [4] Detection of Pesticide Contamination and Freshness in foods using Non-Destructive Methods of IOT&ML [5] SarveshRustagi and Pravesh Kumar 2013 Biosensor andIt’s Application in Food Industry [6] Vijay Kumar, Niraj Upadhay, A.B. Wasit, Simranjeet Singh and Parvinder Kaur, “Spectroscopic Methods for the Detection of Organophosphate Pesticides ,” 2013 in Curr. World Environ., vol. 8, no. 2, pp. 313-318, [7] M. Usman tahir, Salma Iqbal Naik, Salma Rehman and M.Shahzad, “A quantitative analysis for the toxic pesticide residues in marketed fruits and vegetables in lahore, pakistan,” Dec. 2009 in Biomedica., vol. 25, pp. 171 – 174, [8] A. J. Dhembare, “Bitter truth about fruit with reference to artificial ripener,” 2013 in Archives of Applied Science Research, vol. 5, no. 5, pp. 45-54] Horiguchi, Takuro. “Drifting pesticide detection based on Attenuated total reflection of infrared spectroscopy”, 2011 In proceedings of IEEE SICE Anuual Conference [9] Bhandari, A. K., A. Kumar, and G. K. Singh. 2012 Feature Extraction using Normalized Difference Vegetation Index (NDVI): a case study of Jabalpur city.in proceedings of Procidia Technology [10] Riczu, Péter, Attila Nagy, ÉvaBozsik, BernadettGálya [11] PéterÁkosMesterházi, and JánosTamás 2013 Complex Vegetation Survey in a Fruit Plantation by Spectral Instruments in Journal of Agricultural informatics, vol n4, page no. 37-42 [12] Bhadekar, Rama “Developments in analytical methods for Detection of pesticides in environmental samples.” 2011 inAmerican Journal of Analytical Chemistry. [13] M. Tsukioka, H. Ishizawa, T. Takano, H. Yamada, K. Nakagawa, N. Tanaka, “Classification of Pesticide Residues in the Agricultural Products Based on Diffuse Reflectance IR Spectroscopy”, 2007 in proceedings of SICE Annual Conference, pp.216-219 [14] T. Takano, H, Ishizawa, K. Honda, H, Yamada, “Detection Drift and Classifying Concentration of Pesticide on theBasis of Infrared Spectral Feature Analysis”, 2009 in Journal of The Illuminating Engineering Institute of Japan,Vol. 93, page no.5, pp.267-272,. [15] Correia?Sá, Luísa “Optimization of QuEChERS method for The analysis of organochlorine pesticides in soils withDiverse organic matter.” 2012 Journal of separation science,Page no. 1521-1530 [16] Rodrigues, Dasciana 2011 Determination of insecticide Residues in vegetal fruits in Chromatography Research International [17] Bueno, D., et al. “Characterization of biosensors for the Detection of pesticides using a sequential injection analysis System.” Sept. 2010 in Electrical Engineering Computing Science and Automatic a Control (CCE), pp.429-433,. [18] Rodriguez, Ian R., and Grady L. Miller. “Using a Chlorophyll meter to determine the chlorophyllConcentration, nitrogen concentration, and visual quality ofSt. Augustinegrass.” 2000 in HortScience

Copyright

Copyright © 2024 Sunku Uma Maheswari, Shaik Mohammad Adil, Thummala Vamsi, Geetha Charan, Segiji Sravan Muni Kumar, A Krishna Mohan. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET60541

Publish Date : 2024-04-18

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online